Customer success story: Keeping the production rolling with Samesor

Insight

Customer Success story: KEEPING THE PRODUCTION ROLLING WITH SAMESOR

Limtré Virnet – Customer Success Story

For over three decades, Limtré Virnet’s factory in Iceland has relied on a Samesor roll-forming machine as the backbone of its production. Thanks to Samesor’s expertise in upgrades and maintenance, that same machine continues to run efficiently today—delivering even better quality than before. This is a story of trust, smart solutions, and a partnership built to last.

A reliable partnership and machines that stand the test of time

Jakob Guðmundsson, Director of production at Limtre Virnet, oversees operations at a factory located in Borgarnes, a small town just outside Reykjavik. The factory has relied on Samesor’s expertise for many years to maintain and upgrade their machinery.

– I started working here 20 years ago, and the Samesor machine was already in place. The machine dates back to 1997. Back then, I started as a production worker and got to know the machine quite well. Shortly after, I was promoted to production manager, Guðmundsson tells.

This machine has been rolling strong thanks to active collaboration with Samesor. The collaboration began in 2008 when the factory contacted Samesor to upgrade the machine’s software.

– The software upgrade went smoothly, and the machine kept running reliably. Last year, we reached out to Samesor again. The roll forming system was showing signs of wear and Samesor’s team suggested upgrading the roll formers while retaining the steel frame, which turned out to be the perfect solution for us. The upgraded machine is still in full production today, describes Guðmundsson.

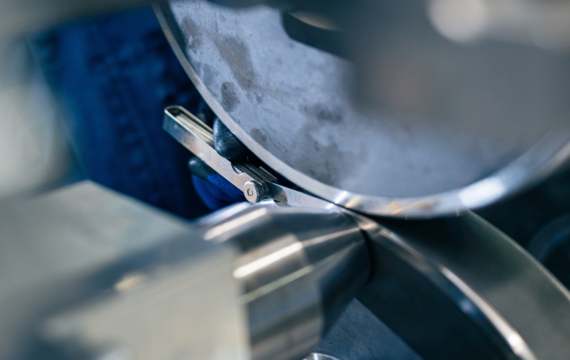

The machine before.

Added value from Samesor

Samesor’s support has gone beyond maintaining and upgrading Limtre Virnet’s roll-forming machine.

– They’ve even been able to help us maintain other machines from different manufacturers. Recently, Samesor provided spare parts for a machine that wasn’t originally bought from them. That kind of flexibility and willingness to assist is very valuable to us, Guðmundsson explains.

– Even if there’s no immediate sale, they’re always happy to share their expertise. That level of service is rare, Guðmundsson notes the value of Samesor’s customer service.

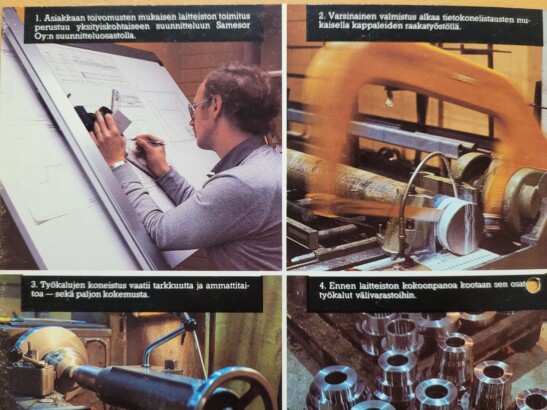

The machine after the upgrade.

Sustainability through upgrades

Upgrading machines rather than replacing them is not just a cost-effective solution for Limtre Virnet factory—it’s also a more sustainable choice.

– Transportation to and from an island like Iceland is expensive, so we’re very happy that we don’t need to replace the entire machine. With Samesor’s help, we’ve been able to upgrade key components, reducing waste and extending the machine’s lifespan. That’s important for both our business and the environment, says Guðmundsson.

The cornerstones of successful collaboration – Communication and Quality

For Guðmundsson, the collaboration with Samesor has been defined by their strong communication and commitment to solving problems.

– The team at Samesor really understood what we were trying to achieve. I felt like they went out of their way to help us, which I truly appreciated. Now that the machine is upgraded, we’ve been able to deliver better-quality materials to our customers. That was our goal, and it’s been fully achieved—we’re now complaint-free, Guðmundsson rejoices.

The collaboration has evolved through the years and Jakob Guðmundsson also visited Samesor’s facilities in Finland a few years back.

– I was lucky enough to visit Samesor’s factory in Kuopio, where I was greeted like royalty. Seeing their production line and the quality of their work firsthand was very reassuring, Guðmundsson tells with a smile.

When asked if they would recommend Samesor, Guðmundsson’s answer is unequivocal:

– Absolutely. Samesor stands out for their excellent quality and service. They may not be the cheapest, but the quality they provide is worth every penny. I’m delighted to have this connection and know I can always reach out for advice.

With the freshly upgraded roll forming machine running smoothly, Limtré Virnet’s factory is well-equipped to continue delivering high-quality materials to their customers for years to come.

Ready to get things rolling?

Worldwide delivery and customer care