High efficiency and cost-effectiveness

Roll forming offers fast construction timelines compared to traditional methods. The prefabricated components can be manufactured even off-site and assembled quickly, reducing project durations. Additionally, the predictability and precision of metal components minimize construction delays and errors. This efficiency translates into cost savings, making roll forming an economical choice for many industries.

Customization of designs and patterns

Roll forming enables the creation of custom profiles tailored to individual needs, providing architects and engineers with greater design flexibility, and allowing them to create innovative and efficient structures and patterns. Are you interested in designing a whole new product to your repertoire? Don’t hesitate to contact us! Our experts are at your service, when you are looking for new profiles or features that change the rules of the game.

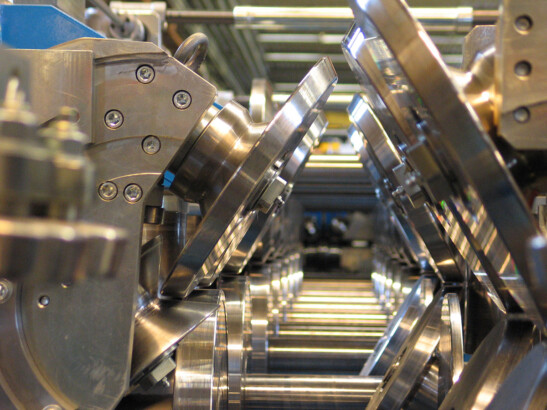

Scalability of Roll Forming

The scalability of roll forming is an important aspect to highlight. If your business is aiming to grow, this is good news to you: After the initial setup, expanding production to meet growing demand is relatively simple. Our modular production lines can be adjusted at any point in your business’s lifecycle, allowing you to add new modules as needed. For example, these additional devices help you boost the process throughout your entire production chain and add value to your customers.

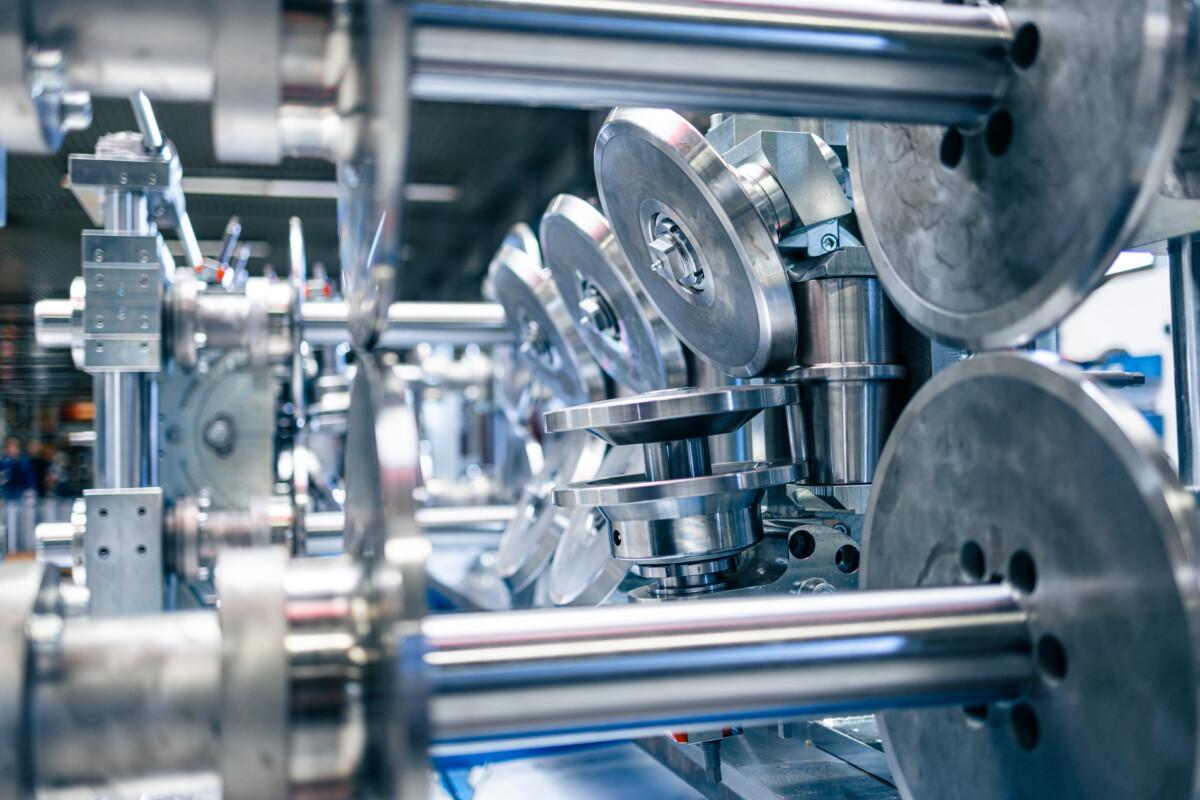

Precision and structural integrity

Roll forming ensures precise shaping of the metal, resulting in components that meet exact specifications with a high-quality finish. Additionally, roll forming excels in creating intricate shapes while preserving the structural integrity of the metal. This enables manufacturers to produce complex and detailed shapes without compromising strength and durability.

Material versatility

Roll forming process works with versatile materials, from steel, aluminum and stainless steel to copper. This versatility enables creation of intricate designs that meet specific engineering requirements and aesthetic preferences, making roll forming a valuable process in various industries.

The reduced labor time

Thanks to its high level of automation, roll forming machines typically require fewer operators compared to other metal fabrication methods. The flexible process allows for the fast and efficient production of prefabricated structures for various types of construction projects. This reduction in manpower can lead to significant savings on labor costs both in production and on-site.

Material saving and sustainable solution

Materials used in roll forming are corrosion-resistant and dimensionally stable, which contributes to the product’s longevity which few construction materials can match. Roll forming offers also a significant advantage in minimizing material waste. It efficiently utilizes sheet metal, and any leftover materials can usually be recycled. This sustainability aspect makes roll forming a preferable choice compared to other methods.